Principles of Data Reduction and Reference Parameter Selection

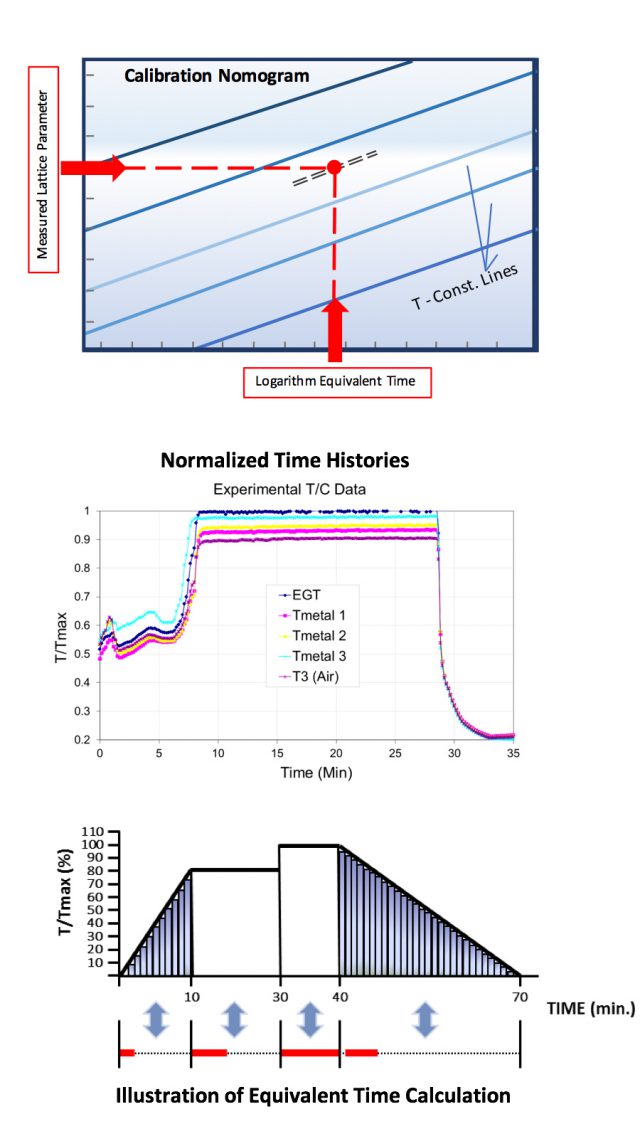

The calibration nomogram is created for a batch of crystals. Changes in the crystal lattice are related to temperature and time using thousands of well controlled experiments, and a high accuracy S-type platinum thermocouple as the standard.

The crystal responds throughout the duration of testing. Changes in the crystal lattice are accumulated in response to the different temperatures encountered over the full length of the test. Thus, whether a peak temperature is encountered at the beginning, at the end or repeatedly throughout the time of testing, the crystal responds and accumulates all of the changes. What is reported is the max temperature encountered during the entire period of testing. It is therefore important to avoid overshoots when ramping up to max temperature and to have an accurate test profile for data reduction.

It is also important to note that the UCTS response to temperature is fast. As long as the test article where the UCTS is embedded experiences the temperature, even if it is held only for some seconds, it will be ”felt” by the sensor. If you have questions about the duration of exposure to temperature, the impact of Heat Transfer Inertia with respect to the selected reference, and methods to help optimize your application, please contact us.

The time history or histories provided for data reduction must reflect the heat transfer reality at the location of the crystals. Knowing the time spent at each regime enables the calculation of equivalent time at max. One of the most critical parts of OEM engineering is the comparative study of the available options for the choice of “Ref. Thermocouple” which would be used to obtain representative Time Diagram during the engine test.

LGTL Global provides support to customers throughout the project life cycle. Reference Parameter selection is a popular topic for discussion. One of the ways we are able to participate in this effort is by evaluating the systematic errors associated with the choice of candidate reference thermocouples.